Custom Molding

Our Services

The 7‑Step Custom Molding Process at Pacific Injection

Molding

Meeting — We Listen First. Always.

We start with discovery: goals, constraints, compliance, and success criteria.

Design — We Engineer With You, Not Just For You

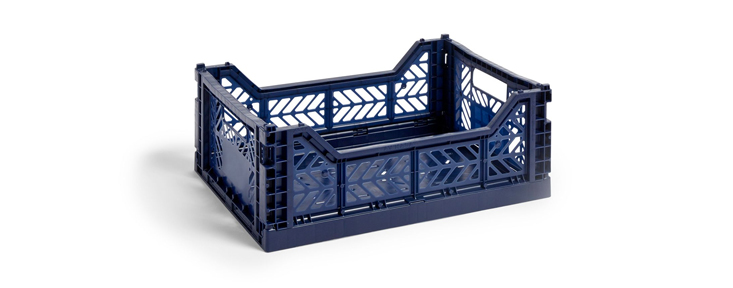

Models tailored to your workflow: handles, stacking, ventilation, and labeling.

Prototype — See It. Feel It. Test It.

Rapid prototypes for form, fit, and function before you scale up.

Analysis — Let the Data Do the Talking

FEA, impact, load, and thermal checks ensure real‑world performance.

Initial Test — Field‑Proven Performance

Short‑run builds to validate ergonomics, stacking, washing, and transport.

Sustainability — Designed to Last. Built to Recycle.

Materials and processes chosen for long lifecycle and recyclability.

Recycling — We Close the Loop

End‑of‑life take‑back and regrind options keep plastics in circulation.

Step 1: Meeting — We Listen First. Always.

Before we build anything, we build understanding.

This step isn’t just about gathering specs—it’s about strategic alignment. We take the time to understand your product, your workflow, and the problems you’re trying to solve.

We ask the tough questions:

- What are you storing, shipping, or stacking?

- Are your current containers underperforming, breaking, or wasting space?

- What handling equipment do you use—forklifts, conveyors, racking systems?

- Any sanitation requirements, food‑grade standards, or industry regulations?

- Do you need bins that nest, stack, drain, or lock?

Whether you’re in food processing, agriculture, warehousing, or cold‑chain logistics, we align solutions with your exact goals—not assumptions.

This is not a transaction—it’s a partnership. Our goal? Co‑create a solution that works in your real‑world environment, not just in a brochure.

Step 2: Design — We Engineer With You, Not Just For You

Here’s where your idea begins to take shape—literally.

We use CAD to translate your needs into a manufacturable design. Your feedback is integral at every step.

What goes into the design phase?

- Tailored CAD modeling based on your specs, handling systems, and load requirements

- Ergonomic features: grips, interlocking lids, secure bases, label holders

- Reinforcements for stacking strength and longevity

- Optional elements for drainage, venting, or anti‑slip textures

- Material selection informed by environment, regulatory requirements, or reuse goals

We factor in weight‑to‑strength ratios, durability targets, and cost‑efficiency—so you get a container that performs without wasted material or money.

Bottom line: Every curve, edge, and groove is designed for a reason—yours.

Step 3: Prototype — See It. Feel It. Test It.

No more crossing your fingers at the production stage.

Once the design is approved, we produce a tangible prototype—an early production‑quality version of your product. This allows you to test and validate the solution in real‑world conditions before committing to full‑scale manufacturing.

Why prototyping matters:

- Visualize and feel your container before production begins

- Test fit and function on your floor: racking systems, pallet jacks, conveyors, cold storage, etc.

- Check ergonomics—how does it grip, stack, drain, or hold up?

- Provide immediate feedback to tweak size, wall thickness, handles, or texture

This stage is collaborative and crucial. You’re not just approving a drawing—you’re experiencing your product.

Step 4: Analysis — Let the Data Do the Talking

We don’t gamble with quality. We validate it—with science.

Our engineering and QA teams subject your prototype to rigorous testing using simulation software and real‑world stress tests. We ensure your container is engineered to withstand your most demanding applications.

What we test:

- Weight‑bearing performance, both static and dynamic

- Drop impact and durability in high‑friction and high‑handling environments

- Thermal resistance for extreme cold or heat (freezers, sun exposure, wash‑downs)

- UV protection for outdoor use or long‑term storage

- Chemical and material compatibility with food safety, agriculture, or industrial needs

If the container cracks, warps, slips, or degrades—it’s back to the drawing board. If it passes with flying colors? We’re almost ready to scale.

This step ensures your product won't just look good—it will perform brilliantly under pressure.

Step 5: Initial Test — Field‑Proven Performance

Once we’ve stress‑tested your prototype, it’s time for field testing—because real‑life always has surprises.

We manufacture a short‑run production batch, allowing you to trial the containers in the environments they were built for.

What you get:

- A mini production batch delivered to your site

- Real‑world testing with your team, machinery, inventory, and processes

- Insights into cleaning cycles, transport conditions, and stacking dynamics

- Opportunity to fine‑tune details before committing to full‑scale production

This step is the final safeguard. It ensures the solution not only meets our standards—but works seamlessly in your workflow.

Step 6: Sustainability — Designed to Last. Built to Recycle.

At Pacific Injection Molding, sustainability isn’t just good PR—it’s good practice. We engineer containers that reduce waste, extend lifespan, and lower your environmental footprint.

What makes our process eco‑conscious?

- Recyclable and reusable polymers chosen for strength and longevity

- Efficient mold designs that minimize material waste during production

- Smart part geometry that reduces weight without compromising strength

- Energy‑efficient machines that lower operational carbon emissions

- Local manufacturing in Canada to reduce transport emissions across North America

We’ll help you meet your corporate sustainability goals, comply with industry regulations, and build a supply chain that’s as responsible as it is reliable.

Step 7: Recycling — We Close the Loop

Even the strongest containers reach the end of their lifecycle. We don’t want them in a landfill—we want them back.

Through our Reclaim & Recycle program, we make it easy to dispose of your worn‑out totes, bins, or parts responsibly.

What our recycling process includes:

- Easy return or pickup of used containers

- Processing of high‑performance plastics for reuse

- Closed‑loop systems for high‑volume clients (think circular economy)

- Support for your internal ESG initiatives and reporting needs

We’re proud to offer a full‑circle solution—from design to disposal—and to help our clients do the same.

One Process. Endless Possibilities.

Our 7-step process isn’t just a checklist—it’s a quality commitment. It's how we’ve earned the trust of industry leaders in logistics, agriculture, cold storage, food production, and industrial warehousing.

Whether you're looking for:

- A lightweight, nestable bin with ergonomic grip

- A heavy-duty industrial container that resists corrosion

- A food-grade stackable tote that drains and washes easily

- Or a completely unique plastic product made from scratch...

We’ve got you covered—from idea to impact.

Why Choose Pacific Injection Molding?

Built to Perform.

Our containers are engineered to survive the harshest environments—over and over again. Think heavy loads, extreme temps, constant handling, and years of wear.

Designed for Your Workflow.

We design for your specs, not ours. From size and shape to features like interlocking bases and drain holes—we build to fit your processes perfectly.

Industry-Tested. Customer-Trusted.

From logistics and food processing to warehousing and agriculture, we’ve served hundreds of clients across North America—and they keep coming back.

Made in Canada. Distributed Across America and Mexico.

With a full-service manufacturing facility in Canada and partnerships across the U.S., Canada, and Mexico, we’re proud to deliver local service with continental scale.

Service That Sticks.

We’re not just here to ship containers—we’re here to solve problems. Our customer service team is ranked #1 for a reason: we’re fast, responsive, and always ready to help.

Who We Serve?

- Warehousing & Logistics – Stackable, space-saving containers built for forklift and racking systems

- Agriculture – Food-safe, ventilated, and moisture-resistant bins for produce, grains, or live goods

- Manufacturing & Industrial – Rugged, reusable containers for parts, tools, and inventory

- Cold Storage – Temperature-stable materials that perform in freezer environments

- Food & Beverage – Containers designed for hygiene, cleaning, and regulatory compliance

No matter your industry, if you need custom-molded containers—PIM delivers.